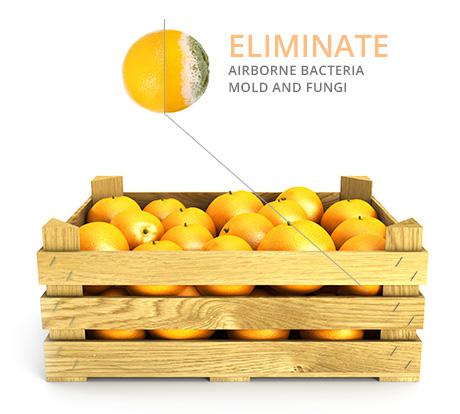

Preserving quality made easy

Proper refrigeration is an absolute necessity for protecting quality of fruits and vegetables, but it’s not enough. Taking additional actions is necessary too.

Today, storing fruits and vegetables properly involves not just controlling temperature and humidity, but also the reduction of airborne pathogens and ethylene levels.

Miatech has developed a technology that eliminates ethylene and bacteria as air passes through it.

Growers & distribuitors

Stop Premature Ripening

Premature ripening characterized by softening and color changes is one of the primary causes of lowering commercial value of fresh fruits and vegetables, in some of the cases leading to the point when produce is no longer marketable. The chief reason for premature ripening is ethylene gas; it triggers and promotes ripening process for ethylene sensitive produce like apples, tomatoes, or avocadoes. Removal of ethylene gas from cold rooms is critical for preventing premature ripening and prolonging shelf life of stored fresh produce items.

Premature ripening characterized by softening and color changes is one of the primary causes of lowering commercial value of fresh fruits and vegetables, in some of the cases leading to the point when produce is no longer marketable. The chief reason for premature ripening is ethylene gas; it triggers and promotes ripening process for ethylene sensitive produce like apples, tomatoes, or avocadoes. Removal of ethylene gas from cold rooms is critical for preventing premature ripening and prolonging shelf life of stored fresh produce items.

Bio Turbo employs a patented technology for removing ethylene gas from cold rooms and thus significantly reduces the risk of premature ripening.

Prevent Mold and Bacterial Contamination

Another quality threat oftentimes leading to fresh fruits and vegetables waste is pathogens contamination. Mold spores and bacteria float in the cold room air remaining active for prolonged periods of time, waiting for favorable conditions. Neutralizing this contamination threat largely relies on cleaning the air from pathogens.

Another quality threat oftentimes leading to fresh fruits and vegetables waste is pathogens contamination. Mold spores and bacteria float in the cold room air remaining active for prolonged periods of time, waiting for favorable conditions. Neutralizing this contamination threat largely relies on cleaning the air from pathogens.

It’s relatively easy to with Bio Turbo. Bio Turbo’s cell destruct filter pierces cell walls making a preemptive strike against molds, bacteria and viruses.

Processing plants - creating cleaner enviroment

Minimize Contamination from Airborne Bacteria

Many experts observe that airborne contamination is strongly suspected as the cause of some pathogenic contamination including bacteria (e.g. Lysteria monocytogenes) and various kinds of molds. Compared to water and dirt, air probably is a less of a threat to produce safety, but threat remains a threat and eliminating it is of the utmost importance.

Many experts observe that airborne contamination is strongly suspected as the cause of some pathogenic contamination including bacteria (e.g. Lysteria monocytogenes) and various kinds of molds. Compared to water and dirt, air probably is a less of a threat to produce safety, but threat remains a threat and eliminating it is of the utmost importance.

Bio Turbo effectively reduces contamination threats by cleaning the air from airborne bacteria, viruses and mold spores.

Protect Produce Quality

The other issue is maintaining a good quality of fruits and vegetables intended for processing. While in cold rooms waiting to be processed, fruits and vegetables are a subject to damaging action of ethylene and airborne pathogens. Ethylene induces premature ripening causing discoloration, softening, and faster aging; pathogens promote rot and mold development resulting in higher percentage of produce not fit for processing.

Bio Turbo helps to prolong shelf life of stored produce by removing ethylene from cold rooms.

Packing houses - confidence in quality of each box

Minimize Pathogens Contamination

Tiny bruises and damages to fruits and vegetable are unavoidable, and this is an opening gate for contamination with mold spores and various bacteria. Spoilage is hard to notice because in most of the cases produce doesn’t stay in packaging house for long enough. In fact it’s the consumer whose expectations of shelf life and produce quality are not met.

Tiny bruises and damages to fruits and vegetable are unavoidable, and this is an opening gate for contamination with mold spores and various bacteria. Spoilage is hard to notice because in most of the cases produce doesn’t stay in packaging house for long enough. In fact it’s the consumer whose expectations of shelf life and produce quality are not met.

Bio Turbo cleans the air from mold spores and other airborne pathogens, creates safer environment and reduces threat of bacterial contamination.

Slow Down Natural Ripening Process

Another way to prolong produce shelf life is removing ethylene gas which is responsible for premature ripening. Ethylene gas is a natural ripening hormone, it induces aging process resulting, among others, in discoloration and produce softening. Although the production levels vary for a particular commodity, fruits and vegetables produce ethylene continuously, so the rule of thumb is to use ethylene removal equipment wherever refrigeration is in use.

Another way to prolong produce shelf life is removing ethylene gas which is responsible for premature ripening. Ethylene gas is a natural ripening hormone, it induces aging process resulting, among others, in discoloration and produce softening. Although the production levels vary for a particular commodity, fruits and vegetables produce ethylene continuously, so the rule of thumb is to use ethylene removal equipment wherever refrigeration is in use.

Bio Turbo effectively removes ethylene and significantly delays premature ripening, effectively prolonging shelf life of fruits and vegetables.

Transportation - better protection for transported perishables

Eliminate Ethylene

Ethylene is a natural hormone that promotes ripening and premature decay in fruits and vegetables, all resulting in loss of quality and a shorter shelf life. Many companies make attempts to eliminate ethylene in refrigerated containers by using disposable filters or tubes based on potassium permanganate as an ethylene absorption medium. It does an ok job but its effectiveness depends on human factor: someone needs to remember to regularly replace them, someone needs to make sure filters are in stock and reorder when necessary, and of course someone needs to pay for it on a regular basis.

Ethylene is a natural hormone that promotes ripening and premature decay in fruits and vegetables, all resulting in loss of quality and a shorter shelf life. Many companies make attempts to eliminate ethylene in refrigerated containers by using disposable filters or tubes based on potassium permanganate as an ethylene absorption medium. It does an ok job but its effectiveness depends on human factor: someone needs to remember to regularly replace them, someone needs to make sure filters are in stock and reorder when necessary, and of course someone needs to pay for it on a regular basis.

Bio Turbo is a good alternative to such filters. One of Bio Turbo models was adapted for usage in refrigerated containers: once installed it can work for years. Unlike filters, Bio Turbo performs consistently well, it only requires attention once per year and overall it’s much less expensive to use.

Prevent Pathogens Contamination

Fresh fruits/vegetables are extremely susceptible to airborne pathogens. One rotten apple can literally spoil the entire barrel. This is especially the case during transportation, when using equipment for maintaining proper conditions is complicated. It’s either not possible due to technical reasons or prohibitively expensive to use. Due to these reasons oftentimes shippers do not use any protection from airborne pathogens, risking the entire loads to mold and rots.

Bio Turbo effectively reduces the risks of pathogen contamination by cleaning the air from mold spores and airborne bacteria. Infection will not be able to spread from contaminated items to healthy ones.

Floral – taking care of natural freshness

Protect Flowers from Airborne Pathogens

Botrytis along with other fungal pathogens is one of the primary causes affecting quality of fresh cut flowers. You cannot heal infected flowers but it’s possible to protect the healthy ones by destroying mold spores and airborne bacteria.

Botrytis along with other fungal pathogens is one of the primary causes affecting quality of fresh cut flowers. You cannot heal infected flowers but it’s possible to protect the healthy ones by destroying mold spores and airborne bacteria.

Bio Turbo cleans the air from airborne pathogens, effectively killing virtually all sorts of spores, bacteria and viruses.

Prevent Harmful Effects of Ethylene

Ethylene is another risk factor affecting flowers’ quality. Flowers do not produce much ethylene but they are very sensitive, so even natural levels of ethylene can be pretty harmful. Among others, these effects include uneven flowering, leaf yellowing and even petal drop.

Use Bio Turbo to eliminate ethylene and prevent harmful effects it can have!

Wineries – because wine integrty matters

Prevent Mold Challenges

Higher relative humidity, typically present in wine barrel storages, creates favorable growing conditions for molds. It results in extra man-hours necessary for cleaning walls and barrels, as well as poses significant threats to wine quality by impacting its taste and introducing unwanted odors.

Higher relative humidity, typically present in wine barrel storages, creates favorable growing conditions for molds. It results in extra man-hours necessary for cleaning walls and barrels, as well as poses significant threats to wine quality by impacting its taste and introducing unwanted odors.

Avoid these threats by introducing Bio Turbo. Bio Turbo will effectively clean the air inside wine barrel storage from all sorts of organic matter, including mold spores, airborne bacteria and viruses.

Reduce Evaporative Losses

In a typical storage area without humidification, approximately four gallons of wine evaporate from a standard barrel each year. It’s possible to cut this loses by controlling humidity inside barrel storage which wasn’t always possible due to potential bacterial contamination.

With Bio Turbo it’s not a challenge any more. It’s possible to set desired level of relative humidity without having to worry about possible challenges with mold or bacteria.

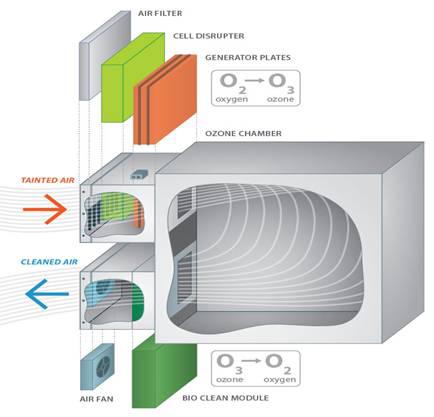

Technology Overview

- Stage 1: air filter

The air filter removes dust and visual particles from the air. - Stage 2: cell disrupter

An anti-microbial chemical is applied to the surface of a specially designed disrupter. It works by rupturing the outer membrane of the cells that make up these airborne pathogens.

With efficiency rates of 99.5%+, this process stops their normal life development, thus destroying the cells. - Stage 3: ozone chamber

This chamber uses the positive effects of ozone to eliminate ethylene gas.

The ozone is safely contained within this chamber and not dispersed throughout the storage area. - Stage 4: bio clean module

In this final stage, a catalyst is used to change the ozone into clean oxygen.

The catalyst creates a reaction that breaks down the ozone molecule.

From here the clean oxygen is released back into the environment.

Patented Technology

Bio Turbo technology of employing ozone in a completely new way is unique in its kind and this is confirmed by patent issued by United States Patent and Trademark Office.

Bio Turbo technology of employing ozone in a completely new way is unique in its kind and this is confirmed by patent issued by United States Patent and Trademark Office.

The Bio-Turbo, which uses a four stage treatment process, is both affordable and effective. Each part of the process takes place within the Bio-Turbo unit, so nothing leave the Bio-Turbo except clean air that is free of ethylene and airborne pathogens.

Completely safe

Ozone is aggressive and exposure to ozone in high concentrations can be dangerous. However it’s not the case with Bio Turbo.

Ozone is aggressive and exposure to ozone in high concentrations can be dangerous. However it’s not the case with Bio Turbo.

Bio Turbo is the first technology to harness the power of ozone without exposing people or equipment to any risks, ozone is securely locked inside the reaction chamber and it never leaves the unit.

Security Measures

Safety switches automatically shut down ozone production in case there’s any problem with Bio Turbo components.

Safety switches automatically shut down ozone production in case there’s any problem with Bio Turbo components.

This was done to make sure no ozone is ever released to the environment.

Low Maintenance

In comparison with competing technologies Bio Turbo is very maintenance friendly.

In comparison with competing technologies Bio Turbo is very maintenance friendly.

It’s only necessary to replace air filters from time to time and ozone plates once per year.

Replacing it is very easy and can be a person without any special technical background.

The Bio-Turbo is available in several sizes to accommodate many different applications. It is easy to install, and nearly maintenance free.

- Bio Turbo 100 – for storage rooms up to 100 cubic meters - this can be installed into small cold rooms of vessels, cruise ships, oil platforms;

- Bio Turbo 100i – this can be installed into refrigerated containers (refeers, trucks) – very usefull for fresh fruits & vegetable and cut flowers storage and transportation;

- Bio Turbo 300 – for storage rooms up to 300 cubic meters;

- Bio Turbo 1000 – for storage rooms up to 1000 cubic meters;

- Bio Turbo 6000 – for storage rooms up to 6000 cubic meters.

How and where should Bio Turbo be installed?

Bio Turbo was designed to hang from the ceiling and operate continuously. However you can place Bio Turbo where ever it is the easiest to install and service, so long as it does not interfere with lighting or blocking of refrigeration units.

No pipes connections required.

Bio Turbo was designed to hang from the ceiling and operate continuously, with Remote On and Off control.

We have Bio Turbo installations in: Norway, Netherland, Belgium, UK, Czech Republic, Italy, Ireland, Slovenia, Croatia, Greece, Ireland, Spain, U.A.E., France, Latvia, Lithuania, Poland, Estonia, Hungary, Romania, Armenia, Ukraine, Azerbaijan, Jordan, Tunisia, Thailand, Sri Lanka, Japan, Republic of South Africa, Australia, Peru, USA, Canada, Argentina, El Salvador, Costa Rica, Dominican Republic, Bahamas, Russia, Indonesia, Kazakhstan, China, India, Macedonia, Moldova Republic, Philippines, Malaysia, Singapore, Australia, Kenya, Zimbabwe.

Benefits of using Bio-Turbo technology in deposits of fresh fruits and vegetables, cut flowers, bulbs, shrubs, seedlings:

- To reduce the cross contamination;

- To destroy types of mold and fungi such as Botrytis, black mold, green mold, gray mold;

- To preserve the quality of stored products;

- To create an environment for better storage;

- The flow of goods inside cold room is not affected, storage and removal of goods can be done anytime;

- The store products maintain the quality from the day was started to be stored;

- The Ethylene is completely and permanently eliminated in the cold room, the BIO TURBO system is continously running;

- Low maintenance costs - change the air filter and ozone generator pates once a year;

- Reduced power consumption when using BIO TURBO technology;

- Maintain a high quality level of stored products;

- Extend the life and shelf life of tored products;

- Increase profits.

Notes:

- BIO TURBO is not acting surgical, that can not heal a product that has already been affected (infected) by molds, spores, fungi, viruses. Infested product will die, but the stored products together in the same crate, carton, pallet, cold room will not be infested, aerobic cross-contamination is cut.

- BIO TURBO is the only technology on the market at the moment that solve problems caused by the presence of ethylene and pathogens in postharvest storage rooms.

BIO TURBO – US patent #8293171

- http://bio-turbo.com/

- http://worldmaritimenews.com/archives/98489/bio-turbo-from-miatech-finds-application-at-sea/

- http://www.freshplaza.com/news_detail.asp?id=103056

- http://www.freshplaza.com/news_detail.asp?id=110942

- http://www.freshplaza.com/article/112781/Italy-O.P.O.-Bellaguarda-Good-results-in-melon-conservation-thanks-to-new-air-purification-system-Bio-Turbo

- http://www.freshplaza.com/article/112584/Miatech-air-system-removes-ethylene-and-fungus-in-BUD-Holland-cooling-cells#SlideFrame_1

- http://worldmaritimenews.com/archives/98489/bio-turbo-from-miatech-finds-application-at-sea/

- http://www.organicinfopoint.com/espanol-bio-turbo-control-de-patogenos-aereos-y-etileno/

- http://www.freshplaza.com/article/118431/Bio-Turbo-proven-to-prevent-vegetable-cross-contamination

- http://www.freshplaza.com/article/118429/Bio-Turbo-now-adapted-for-use-in-refrigerated-trucks-and-reefers

- http://www.freshplaza.com/article/140762/Miatech-Postharvest-Solution-makes-its-way-to-Kriegler-Farms-South-Africa?utm_campaign=newsletter&utm_medium=ed6&utm_source=s1

- http://www.freshplaza.com/article/156999/New-opportunities-for-removal-of-bacteria-and-fungi-in-fruit-laboratories

For more information we invite you to contact us or send us an inquiry and we will personally present the added value that the advanced MIATECH perishable control technologies will bring to your business!

Regards,

International Field Manager

9480 SE Lawnfield Road

9480 SE Lawnfield RoadClackamas, OR 97015, USA

Phone: (503) 659-5680, ext. 576

Fax: (503) 659-2204

Skype Phone: +1 503-210-5347

Skype Name: ioan.matei-mateo

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.miatech.org

Authorized dealer for Macedonia, Serbia, Albania and Kosovo

str. Ivan Cankar 46b, Skopje

str. Ivan Cankar 46b, SkopjePhone: +389 70 235 961

Phone/Fax: +389 2 2032 822

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.gorenjsko.com